Things to know about BILSTEIN shock absorbers for motorhomes

What you need to know about shocks

Shock absorbers improve a vehicle’s stability by absorbing vibrations, resulting in better control when braking or swerving. Specially optimised shock absorbers offer more comfort, safety and performance than standard products. This is particularly important for motorhomes, as their construction places special demands on the vehicle’s damping.

By the way, shock absorber erosion is a gradual process. If you notice a change in your motorhome’s handling (steering wobble or body vibration), make an appointment with your workshop immediately.

Tested in the BILSTEIN road test

We tested our camper shock absorbers on a special course in the BILSTEIN driving test under extreme conditions – at high speed, on uneven ground and when driving over edges. We took several weeks to optimise them because we are only satisfied when the incomparable BILSTEIN driving experience is achieved.

Before we go into series production with a product line, we test the prototypes in an elaborate process. In the BILSTEIN road test, we test the behaviour of the shock absorbers under extreme conditions – on poor road surfaces, at high speeds and during evasive manoeuvres. The testers repeatedly drive up and down a special course to determine the ideal characteristics and find settings for maximum safety and performance as well as maximum comfort.

In the BILSTEIN driving test, our expert team consisting of engineers and mechanics tests the real behaviour of the new shock absorbers and the authentic driving feel in various driving situations on a special test course. The team collects data for various measurement and test procedures and optimises the shock absorbers until the incomparable BILSTEIN driving feel is achieved. The most important parameters are safety, comfort and performance.

When driving around the test track, our driving test team measures safety, braking and steering behaviour as well as driving dynamics on the one hand, and pays attention to how the car feels in the various situations on the other. Again and again, they have to remove and install the shock absorbers and optimise the settings. Only when everyone agrees that nothing could be better does a product receive the rating “tested in the BILSTEIN road test”.

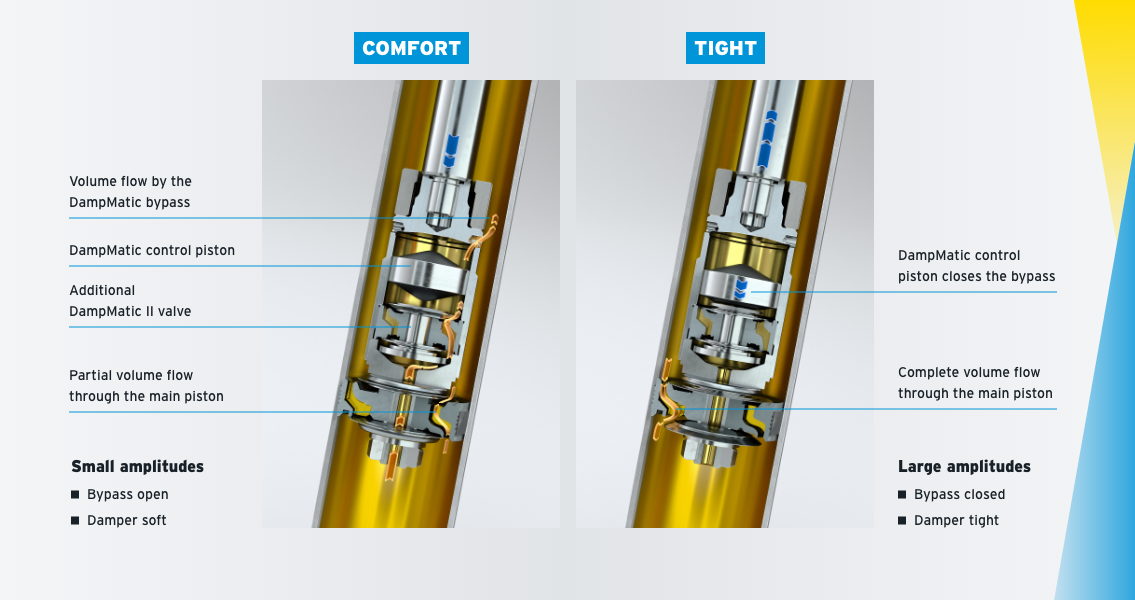

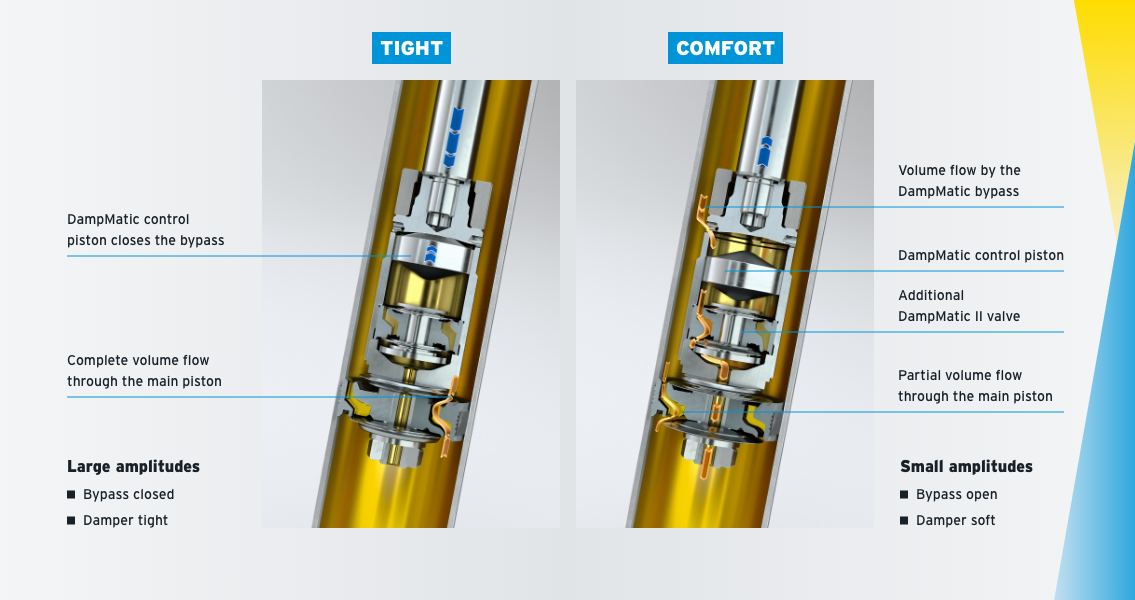

Shock absorber with BILSTEIN’s patented DampMatic technology

The BILSTEIN B6 Camper Advanced features our proprietary DampMatic technology – a passive damping system for gas pressure shock absorbers. Passive suspension systems are actually a compromise between safety, comfort and agility because they cannot adapt to changing driving conditions, i.e. they always follow only one best possible characteristic curve.

This is precisely where the special feature of our DampMatic technology comes into play: Dampers such as the BILSTEIN B6 Camper Advanced can switch between two characteristic curves without a solenoid valve, i.e. purely mechanically because they have a second chamber inside the damper. The vehicle remains stable due to the amplitude deflection -–without additional components, cables or control units. The DampMatic adjustment system reacts very sensitively and quickly: for example, it absorbs noise on rough asphalt and improves rolling characteristics at bridge edges or on cobblestones. The effect is also noticeable in curves and when changing lanes.

WE ARE SOCIAL

Follow us on social media-

-

-

-

-